Introduction

Modern healthcare relies on innovative medical devices, from portable monitors to implantable systems. These technologies demand reliable, compact, and long-lasting power sources. Off-the-shelf batteries often fall short in meeting the stringent requirements of medical applications, creating a need for customized batteries packs designed specifically for these cutting-edge tools.

Medical device battery manufacturers are stepping up to address this challenge, delivering tailored solutions that prioritize safety, efficiency, and adaptability.

As devices shrink in size and grow in complexity, the demand for custom lithium-ion battery packs has surged. These batteries must balance energy density, weight, and thermal stability—factors critical for patient safety and device performance.

The Need for Custom Battery Pack Solutions in Medical Applications

Standard batteries rarely align with the unique specifications of medical devices. For example, wearable glucose monitors require lightweight, flexible custom lithium battery packs, while surgical robots need high-output custom-built battery packs with rapid recharge cycles.

Medical device battery manufacturers collaborate closely with engineers to develop solutions that match precise voltage, capacity, and form-factor requirements.

Additionally, medical environments demand batteries resistant to sterilization processes, temperature fluctuations, and mechanical stress. Custom battery pack design ensures compatibility with these conditions, reducing the risk of failure in critical scenarios.

The Importance of Customized Battery Pack Design

Designing custom lithium-ion battery packs involves more than just adjusting size or capacity. Engineers must consider electrochemical performance, safety protocols, and integration with existing systems.

For implantable devices, such as pacemakers, custom battery manufacturers prioritize ultra-long lifespans and leak-proof construction to prevent hazardous incidents.

Thermal management is another key focus.

Advanced materials and smart monitoring systems are integrated into custom battery pack solutions to prevent overheating—a non-negotiable feature in life-saving equipment.

Custom Lithium-Ion Battery Solutions: Powering Precision

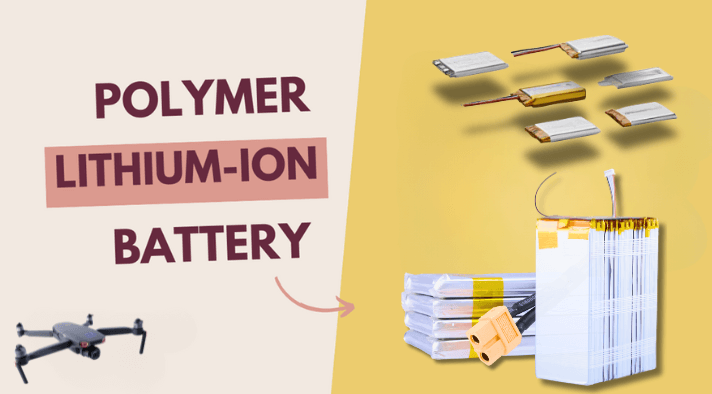

Lithium-ion technology dominates medical applications due to its high energy density and rechargeability. Custom lithium-ion battery packs are engineered to meet niche needs, such as low self-discharge for emergency devices or ultra-thin profiles for hearing aids. Manufacturers leverage modular designs to create scalable solutions, enabling rapid prototyping for emerging technologies.

For instance, custom lithium-ion battery arrays in MRI-compatible devices use non-magnetic materials to avoid interference, showcasing how tailored power systems enable breakthroughs in diagnostics.

Amicell: A Leading Custom Battery Pack Manufacturer

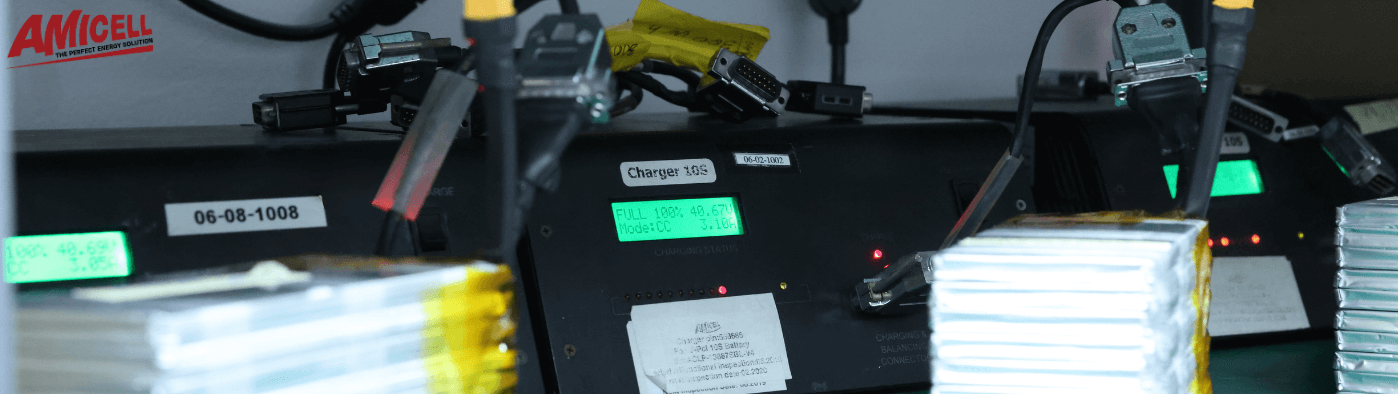

Among medical device battery manufacturers, Amicell stands out for its focus on innovation and compliance. The company specializes in custom battery pack solutions that adhere to strict medical standards, including ISO 13485 and IEC 60601. Their expertise spans from custom battery packs for portable ventilators to ruggedized systems for field-use defibrillators.

Amicell’s collaborative approach ensures clients receive batteries optimized for both performance and regulatory requirements, making them a trusted partner in the healthcare sector.

Key Considerations for Custom Built Battery Packs in Medical Applications

When developing battery packs, engineers must prioritize safety, longevity, and usability. Biocompatibility is essential for wearable or implantable devices, requiring materials that avoid allergic reactions or toxicity. Custom battery pack maker also conducts rigorous testing for shock resistance, cycle life, and energy retention under varying loads.

Furthermore, user-centric features like intuitive charging interfaces and real-time diagnostics enhance device reliability, ensuring seamless integration into clinical workflows.

Safety and Reliability: Non-Negotiable Priorities

Medical devices cannot compromise on safety. Custom lithium-ion battery packs incorporate fail-safes such as overcharge protection, short-circuit prevention, and flame-retardant casing.

Redundant systems are often embedded to maintain functionality during partial failures—a critical safeguard in ICU equipment or infusion pumps.

Medical device battery manufacturers like Amicell validate their designs through accelerated aging tests and real-world simulations, ensuring uninterrupted performance over a device’s lifespan.

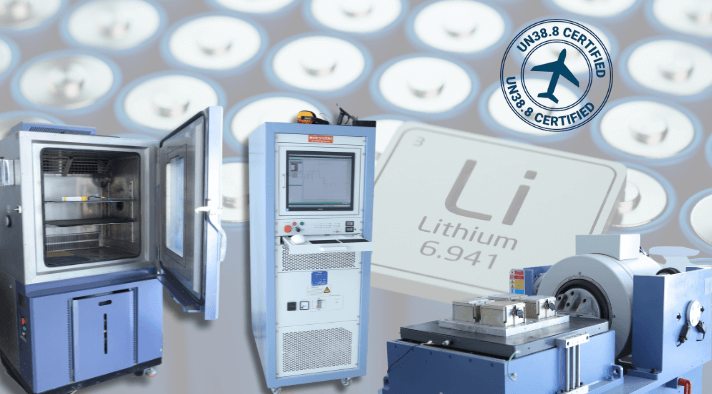

Regulatory Compliance (Including UN38.3)

Compliance with international standards is mandatory for medical batteries. Custom battery pack manufacturers must meet UN38.3 certification for transportation safety, alongside FDA and CE markings for market approval.

These regulations ensure batteries withstand extreme temperatures, altitude changes, and vibration during shipping and use.

Amicell’s custom battery pack solutions are pre-certified for global markets, streamlining the path from development to deployment.

Biocompatibility and Material Safety

For devices contacting skin or internal tissues, custom battery manufacturers use hypoallergenic, non-toxic materials. Nickel-free connectors and medical-grade polymers are common in lithium battery packs for wearables, minimizing irritation risks. Implantable batteries go further, employing hermetic sealing to isolate chemicals from the body.

Custom Battery Solutions for Specific Medical Applications

From telemetry systems to robotic surgery tools, custom battery pack design varies widely. Ambulatory ECG monitors benefit from slim, flexible batteries, while portable ultrasound machines require high-capacity custom lithium-ion battery packs with fast recharge capabilities.

Amicell tailors solutions to these niches, ensuring each battery aligns with the device’s operational demands.

The Future of Custom Lithium-Ion Battery Packs in Medical Devices

Emerging trends like AI-driven diagnostics and IoT-enabled devices will push custom battery pack builder to innovate further. Solid-state batteries, wireless charging, and energy-harvesting systems are poised to revolutionize medical power solutions.

Amicell is at the forefront, investing in R&D to deliver next-generation custom lithium-ion battery solutions that support smarter, more autonomous healthcare tools.

Conclusion

The demand for custom battery pack solutions in medical devices continues to grow as technology advances. From custom lithium-ion battery packs to custom battery packs, tailored power systems are essential for ensuring safety, reliability, and performance in healthcare applications.

Partnering with experienced medical battery manufacturers like Amicell guarantees access to cutting-edge designs that meet stringent regulatory standards and specific operational needs.

As the industry evolves, innovations in battery technology will play a pivotal role in shaping the future of medical devices, enabling smarter, more efficient, and life-saving solutions.