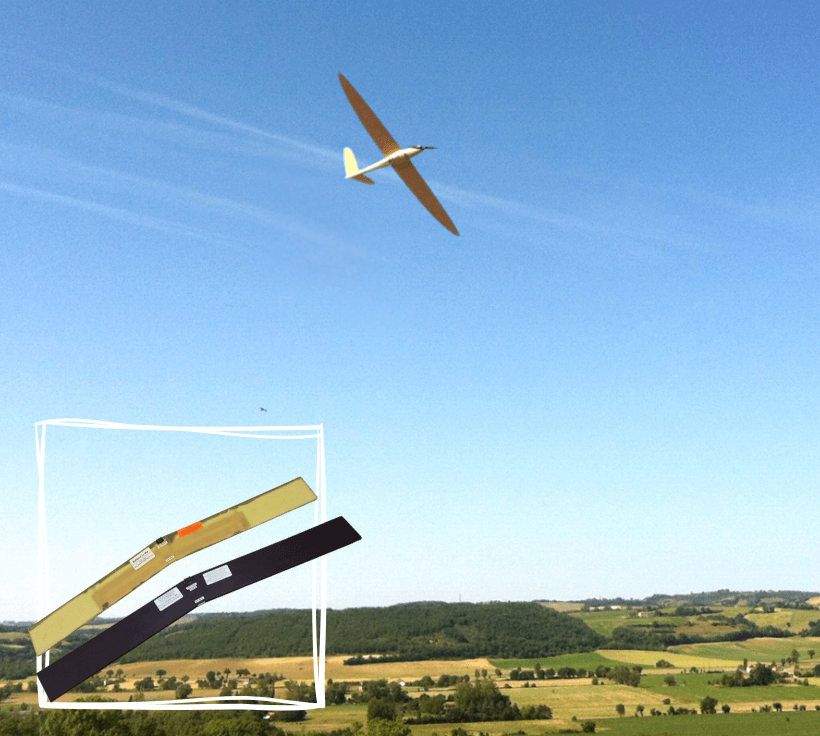

The outcome was a highly efficient, ultra-thin Li-Ion polymer battery pack, meeting all of the customer’s requirements. The battery featured:

- A robust fiberglass casing.

- An optimized cell configuration for maximum capacity.

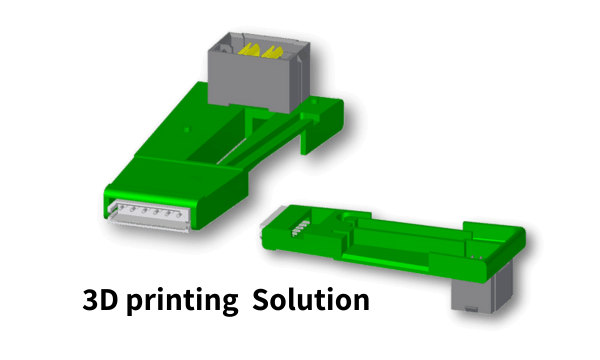

- An innovative wiring solution to manage high power within the confined wing structure.